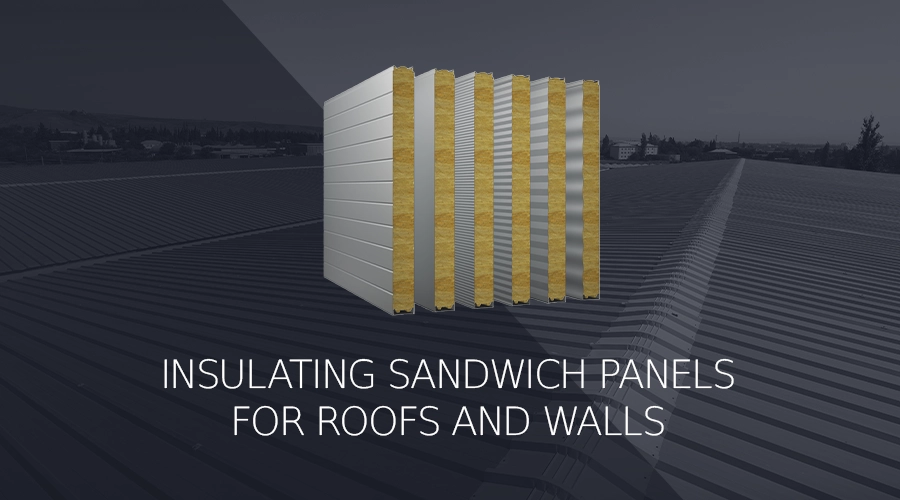

A sandwich panel is a three-layered construction material consisting of metal sheets and an insulating core. It is widely used in modern construction due to its efficiency and versatility.

The core of the panel can be made from:

Polyurethane (PUR/PIR)

Rock wool (Mineral wool)

Polystyrene (EPS)

This combination creates a durable, lightweight, and thermally insulated material, ideal for the fast and high-quality construction of both commercial and industrial buildings.

Thermal Insulation and Energy Efficiency.

Sandwich panels have excellent thermal resistance, contributing to significant energy savings during both heating and cooling seasons. Panels with PUR/PIR cores offer superior thermal insulation.

Sound Insulation.

Especially when using rock wool cores, sandwich panels provide high levels of sound insulation, which is a key advantage for industrial and civil buildings.

Fire Resistance.

Panels with rock wool cores fully comply with fire safety standards. They are non-combustible for a certain period and help prevent the spread of fire.

Easy and Quick Installation.

Produced in factory-controlled conditions, sandwich panels allow for rapid and simple installation, significantly reducing construction time and costs.

Aesthetic Appeal and Versatility.

Available in a variety of colors, surface finishes, and profiles, sandwich panels enable the creation of architecturally appealing and modern building designs.

Sandwich panels are widely used in the construction of:

Warehouse complexes

Factories and industrial facilities

Supermarkets and retail spaces

Recreational buildings

Mobile buildings and containers

Residential buildings

Panels with different core materials and thicknesses can be adapted to various climate conditions and technical requirements.